Our Expertise

Setting a new standard for sustainable packaging

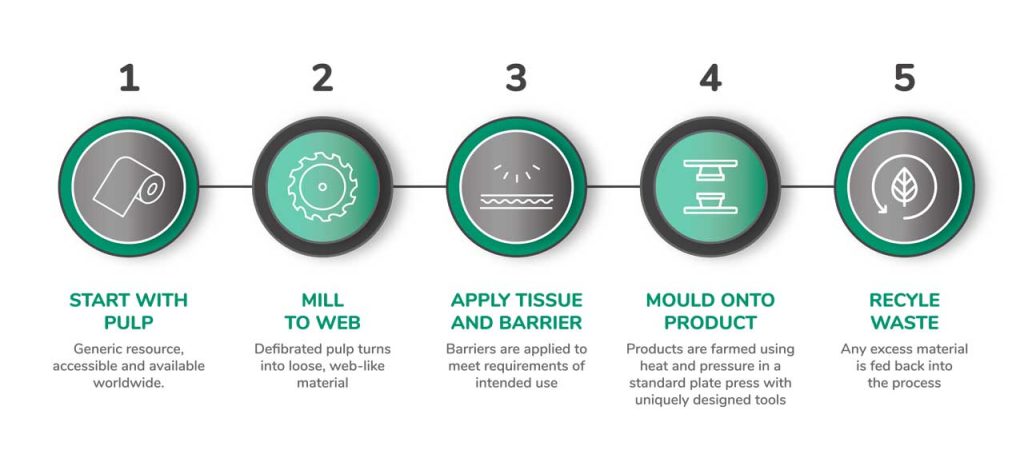

We specialise in barrier packaging, focusing on deeper draw trays and pots, particularly food trays. Using the latest groundbreaking technology that transforms ordinary fibre into packaging.

The Dry Molded Fiber technology uses minimal water and drastically reduces energy consumption, all while producing fibre packaging at speed (up to 10 times faster than traditional moulding methods)

With our own development lab and product design team, we assist companies in converting their existing packaging to a more sustainable fibre alternative.

All our products are bespoke and developed to meet your requirements. Moulded from sustainable fibres, our packaging and products are the ideal solutions to make your company greener.

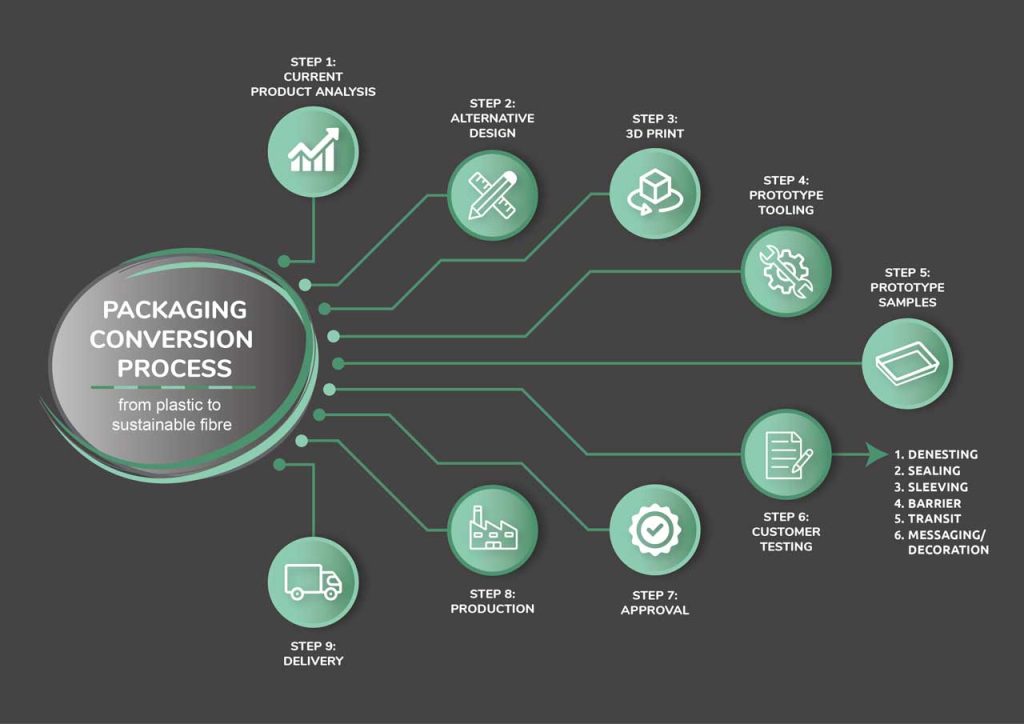

Reverse Engineering

We reverse engineer a more sustainable solution to your existing packaging, a sustainable alternative that runs on your current packing/filling lines without compromise.

No need to change any tooling or sealing/lidding systems.

We offer a complete conversion from plastic to fibre, no capital costs involved!

The Process

Our engineers will analyse the existing packaging and collaborate with the customers to develop new designs.

We will provide 3D prints and validate the product to ensure compatibility.

Once the product design is approved, a prototype tool will be created to provide production quality samples.

The customer can use these samples for their internal testing (denesting, sealing, sleeving, barrier, cooking). Once approved, we will go into production and deliver