Our Sustainability

Fibre packaging, a true solution for a Circular Economy

Pressures from consumers, brands and legislation are paving the way to rethink the way we produce responsibly as well as source responsibly. There is a growing demand for innovative and responsibly packaging solutions.

12 billion tons of flexible packaging are used and thrown away each year, and recycling is simply not catching up with volumes.

It is now well documented that Pulp fibre is more widely recycled than plastics. In fact, over 65% of paper and pulp is recycled annually compared to plastics which is less than 8% annually; with the exception of PET bottles which is close to 15%. Countries that either have a robust recycling system (European) or have a fibre shortage (Middle East and Far East) are averaging over 80%. This is why fibre is recycled 5 to 7 times and recent figures show that in some countries, it is closer to 20.

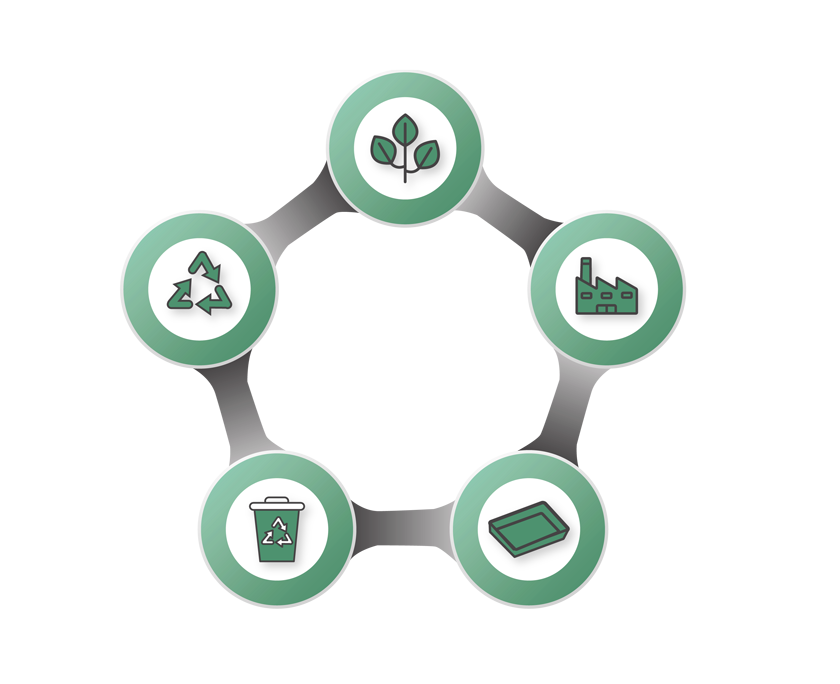

Unlike single-use plastics, dry moulded fibre products are renewable, recyclable, biodegradable and compostable. They will break down naturally, they are highly recycled, they are reused and reinvented several time. Fibre products therefore have much less of an impact on the environment, offering a true circular solution.

Top Recycling Facts

36%

of all plastic produced is currently used to create packaging

25x

the number of time fibre can be recycled

9%

only, of all plastic waste is currently recycled

68%

of all Paper/Pulp is recycled

Fibre Revolution is at the core of our Group vision and is a prime example of our commitment to the future for a more sustainable and innovative packaging industry.

Dry Moulded Fibre Manufacturing is a cornerstone for the packaging industry. It offers sustainable packaging solution that is sourced, manufactured and supplied in the most sustainable way as possible. All of the additives we use in processing our fibre are food safe and chosen for the minimal impact they have on the environment. Our packaging formulations and products are EN13432 certifiable.

RISE, the Research Institute of Sweden, performed a Recycling & Biodegradation Analysis on spoons made from Dry Moulded Fibre. The tested spoon was degraded to 90% after 23 days. According to standardss, the limit is 90% after 180 days. Dry Moulded Fibre spoons were APPROVED for biodegradability according to ISO 14855-1 and shown to have an EXCELLENT RECYCLABILITY according to CEPI REC-21-002. A subsequent climate impact study on spoons made from Dry Moulded Fiber showed that the dry forming process only stands for a mere 7% of the total climate impact. The rest comes from transportation and manufacturing of input materials.