Our Technology

Dry Moulding Fibre, the next evolution in forming sustainable packaging

Dry Moulding

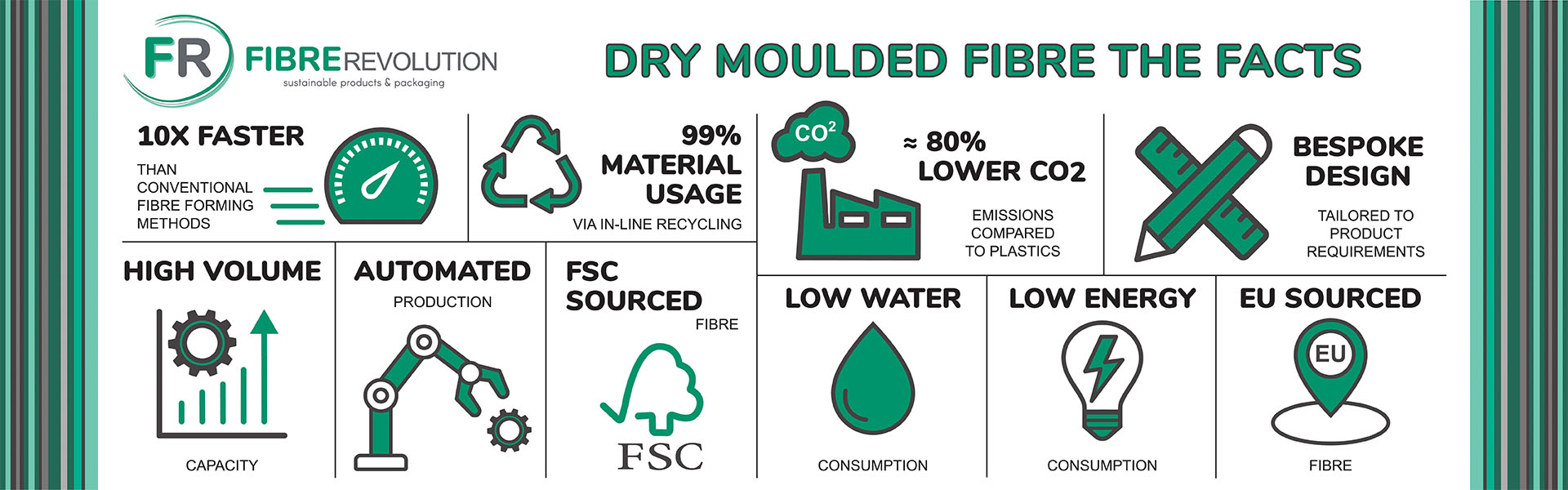

Dry moulding fibre is the latest innovation is formed fibre packaging.

Traditional methods of forming fibre into rigid packaging rely on water and energy to dry the products.

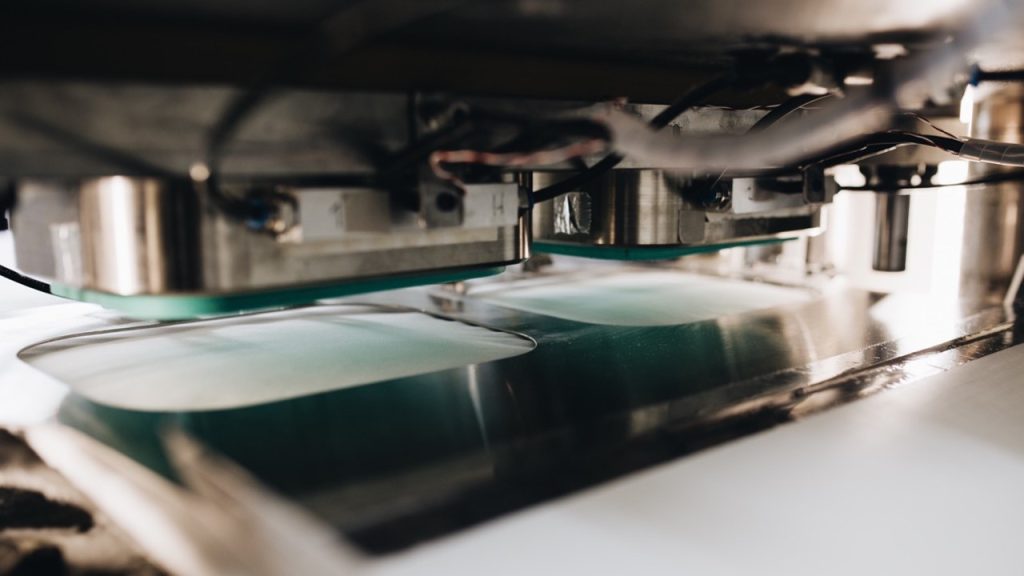

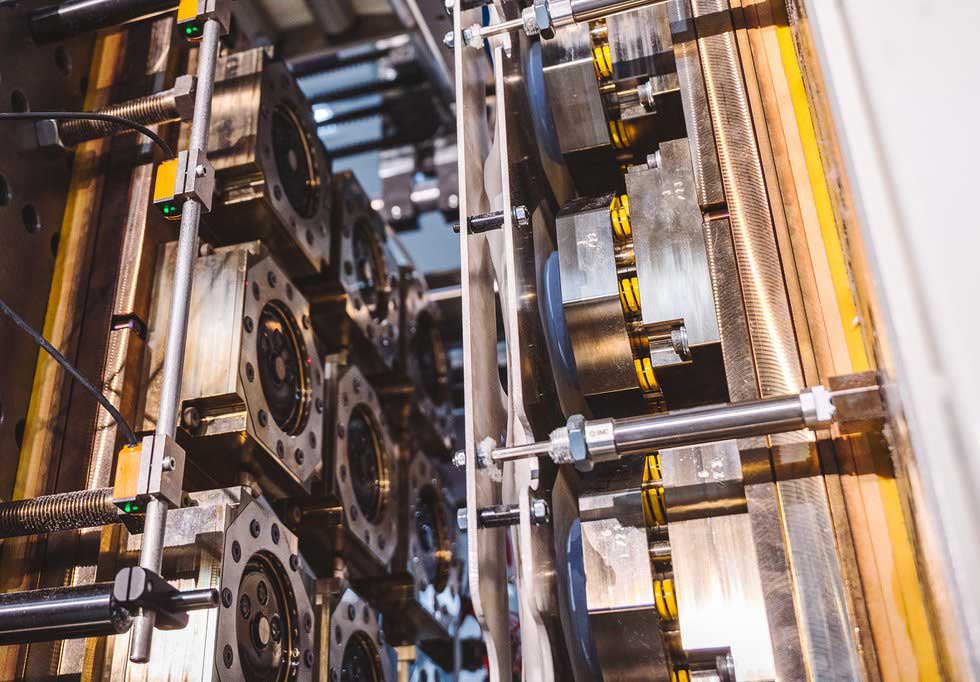

In dry moulding, pulp fibres are pressed under extremely high pressure to make for a very dense substrate; similar to plastic. This new technology managed to take out almost all the water used in standard forming. Resulting in considerable resource and cost efficiency. With no drying stage, the production can operate at speed with short cycle times that matches plastic processing on both price and manufacturing speed.

This in turn, allows to run exceptionally high volume, making it a viable competitor to single use plastic large production runs especially in the food industry. In general terms Dry Moulded Fibre production runs would require MOQs in the region of 5-10 million units.

Uniquely, dry moulded products, can have steep vertical walls (< 3o ) and undercuts. In addition, dry moulded products can be coloured, embossed or debossed on any surface.

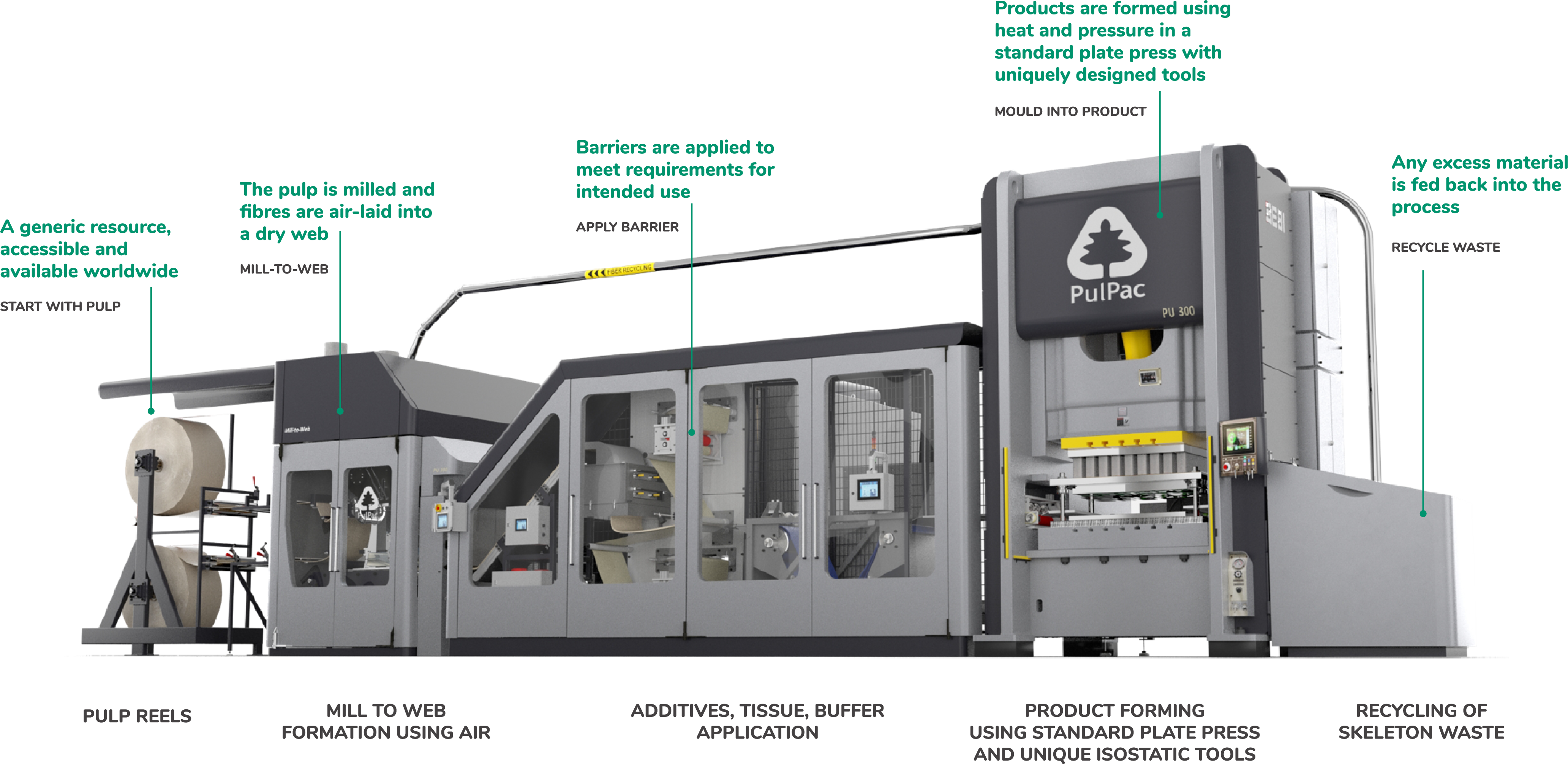

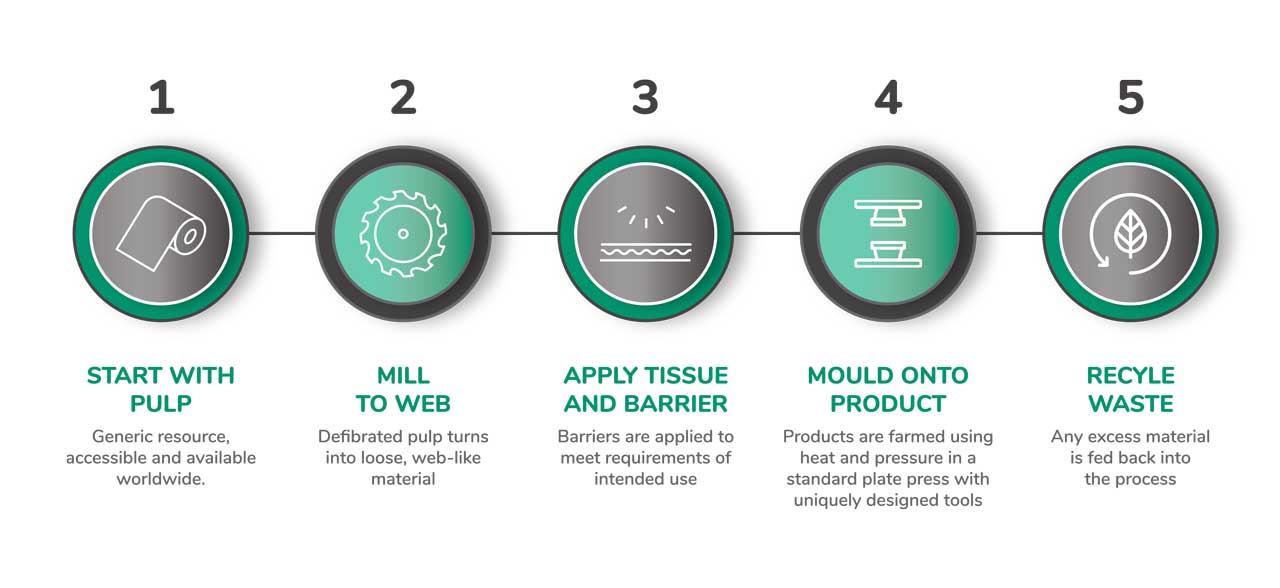

The Dry Moulding Fibre Process

This innovative technology not only saves water and energy during the manufacturing process, utilizes sustainably sourced materials but is commercially scalable and adaptable to deliver packaging solutions that brand owners can trust . Our product technology offers flexibility, to produce different shape and features – a critical point for brand owners who wish to retain they brand identity that consumers know and recognise across its products.

The Facts

The Machine